Water Jet CuttingToday Water Jet is unparalleled in many aspects of cutting and has changed the way many products are manufactured.

Water Jet cutting is preferred when the materials being cut are sensitive to the high temperatures generated by other methods. It has found applications in a diverse number of industries from mining to aerospace where it is used for operations such as cutting, shaping, carving and reaming. The Benefits of Water Jet CuttingEliminates Problems

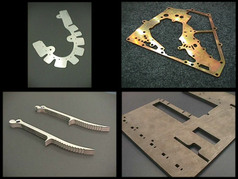

An important benefit of Water Jet cutting is the ability to cut material without interfering with the material's inherent structure. There is no "heat-affected zone" or HAZ. Minimizing the effects of heat allows metals to be cut without harming or changing intrinsic properties. Precise and Intricate Cutting of a Variety of Materials

Water Jet cutters are also capable of intricate cutting of a wide variety of material. The width of the cut typically is very small. This makes very small detail possible in a wide range of applications. A Green Technology

Water Jet is a "green" technology. Water Jets produce no hazardous waste, reducing waste disposal costs. Water Jet cutting machines can cut off large pieces of reusable scrap material that might have been lost using traditional cutting methods. Parts can be closely nested to maximize material use, and the Water Jet saves material by using very small cutting widths. Water Jets use very little water and they eliminate airborne dust particles, smoke, fumes, and contaminates from cutting materials such as asbestos and fibreglass. Water Jet has many benefits over traditional cutting methods, including:

|

Visit our Water Jet Gallery for examples of our Water Jet cut materials*.

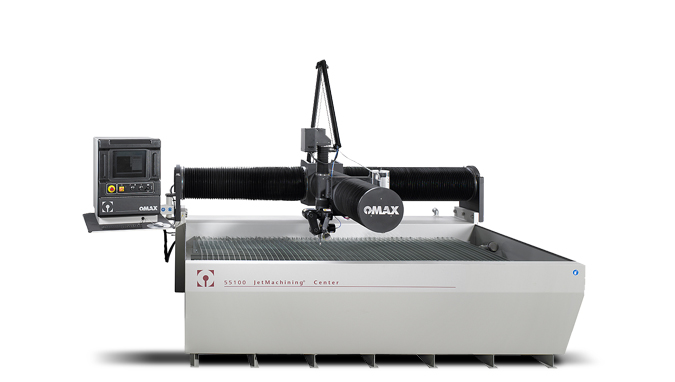

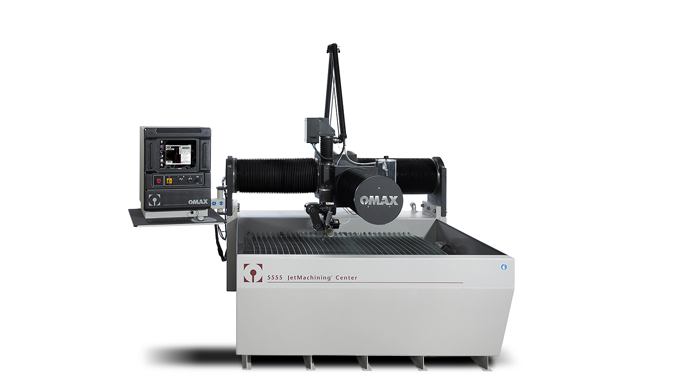

More Water Jet InformationOur JetMachining Centres

Click images* for more detail.

|

Water Jet Cutting Applications

There are many applications for Water Jet cutting including:

- Architectural Metal cutting

- Construction

- Custom Signage

- Aerospace

- Defence

- Electronics

- Medical

- Prototype work

Please ring us on 01452 520983, fax us on 01452 500055 or email our experienced engineers who will advise you about individual materials, their applications and characteristics.

Alternatively you can contact us using our web form – if you mention your telephone number we can call you back.

Tolgar Engineering will work with you to achieve what you want, when you need it.

Alternatively you can contact us using our web form – if you mention your telephone number we can call you back.

Tolgar Engineering will work with you to achieve what you want, when you need it.

*Images courtesy OMAX Corporation.